California Code of Regulations

Title 24, Part 9

California Building

Standards Commission

Based on the 2009 International Fire Code®

California Code of Regulations

Title 24, Part 9

California Building

Standards Commission

Based on the 2009 International Fire Code®

EFFECTIVE DATE: January 1, 2011

(For Errata and supplements, See History Note Appendix)

Public Domain: U.S. Court of Appeals, Fifth Circuit, 99-40632

2010 California Fire Code

California Code of Regulations, Title 24, Part 9

First Printing: June 2010

ISBN 978-1-58001-977-4

Publication Date: June 2010

Copyright © 2010

Held by

California Building Standards Commission

2525 Natomas Park Drive, Suite 130

Sacramento, CA 95833-2936

ALL RIGHTS RESERVEDThis 2010 California Fire Code contains substantial copyrighted material from the 2009 International Fire Code, which is a copyrighted work owned by the International Code Council, Inc. Without advance written permission from the copyright owner, no part of this book may be reproduced, distributed or transmitted in any form or by any means, including, without limitation, electronic, optical or mechanical means (by way of example and not limitation, photocopying, or recording by or in an information storage retrieval system). For information on permission to copy material exceeding fair use, please contact: Publications, 4051 West Flossmoor Road, Country Club Hills, IL 60478. Phone 1-888-ICC-SAFE (422-7233).

Trademarks: “International Code Council,” the “International Code Council” logo and the “International Fire Code” are trademarks of the International Code Council, Inc.

PRINTED IN THE U.S.A.

This document is Part 9 of 12 parts of the official triennial compilation and publication of the adoptions, amendments and repeal of administrative regulations to California Code of Regulations, Title 24, also referred to as the California Building Standards Code.This part is known as the California Fire Code.

The California Building Standards Code is published in its entirety every three years by order of the California legislature, with supplements published in intervening years. The California legislature delegated authority to various state agencies, boards, commissions and departments to create building regulations to implement the State’s statutes. These building regulations or standards, have the same force of law, and take effect 180 days after their publication unless otherwise stipulated. The California Building Standards Code applies to occupancies in the State of California as annotated.

A city, county, or city and county may establish more restrictive building standards reasonably necessary because of local climatic, geological or topographical conditions. Findings of the local condition(s) and the adopted local building standard(s) must be filed with the California Building Standards Commission to become effective and may not be effective sooner than the effective date of this edition of the California Building Standards Code. Local building standards that were adopted and applicable to previous editions of the California Building Standards Code do not apply to this edition without appropriate adoption and the required filing.

Should you find publication (e.g. typographical) errors or inconsistencies in this code or wish to offer comments toward improving its format, please address your comments to:

California Building Standards Commission

2525 Natomas Park Drive, Suite 130

Sacramento, CA 95833-2936

Phone: (916) 263-0916

FAX: (916) 263-0959

Web Page: www.bsc.ca.gov

The 2010 California Building Standards Code (Code) was developed through the outstanding collaborative efforts of the Department of Housing and Community Development, the Division of State Architect, the Office of the State Fire Marshal, the Office of Statewide Health Planning and Development, the California Energy Commission, and the Building Standards Commission (Commission).

This collaborative effort included the assistance of the Commission’s Code Advisory Committees and many other volunteers that worked tirelessly to assist the Commission in the production of this Code.

Governor Arnold Schwarzenegger

Members of the Building Standards Commission

Acting Secretary Tom Sheehy-Chair

Isam Hasenin-Vice-Chair

James Barthman

Craig Daley

Susan Dowty

Tony Hoffman

Christina Jamison

Stephen Jensen

Michael Paravagna

Richard Sawhill

Steven Winkel

David Walls-Executive Director

Thomas Morrison-Deputy Executive Director

For question on California State agency amendments, please refer to the contact list on the following page.

| California Energy Commission | |

| Energy Hotline | (800) 772-3300 or(916) 654-5106 |

| Building Efficiency Standards | |

| Appliance Efficiency Standards | |

| Compliance Manual/Forms | |

| California State Lands Commission | |

| Marine Oil Terminals | (562) 499-6317 |

| California State Library | |

| Resources and Information | (916) 654-0261 |

| Government Publication Section | (916) 654-0069 |

| Corrections Standards Authority | |

| Local Adult Jail Standards | (916) 324-1914 |

| Local Juvenile Facility Standards | (916) 624-1914 |

| Department of Consumer Affairs- Acupuncture Board | |

| Office Standards | (916) 445-3021 |

| Department of Consumer Affairs- Board of Pharmacy | |

| Pharmacy Standards | (916) 574-7900 |

| Department of Consumer Affairs-Bureau of Barbering And Cosmetology | |

| Barber and Beauty Shop and College Standards | (916) 574-7570 (800) 952-5210 |

| Department of Consumer Affairs-Bureau of Home Furnishings and Thermal Insulation | |

| Insulation Testing Standards | (916) 574-2041 |

| Department of Consumer Affair-Structural Pest Control Board | |

| Structural Standards | (800) 737-8188 (916) 561-8708 |

| Department of Consumer Affairs-Veterinary Medical Board | |

| Veterinary Hospital Standard | (916) 263-2610 |

| Department of Food and Agriculture | |

| Meat and Poultry Packing Plant Standards | (916) 654-1447 |

| Dairy Standards | (916) 654-1447 |

| Department of Public Health | |

| Organized Camps Standards | (916) 449-5661 |

| Public Swimming Pools Standards | (916) 449-5693 |

| Asbestos Standards | (510) 620-2874 |

| Department of Housing and Community Development | |

| Residential-Hotels, Motels, Apartments, Single-Family Dwellings | (916) 445-9471 |

| Permanent Structures in Mobilehome and Special Occupancy Parks | (916) 445-9471 |

| Factory-Built Housing, Manufactured Housing and Commercial Modular | (916) 445-3338 |

| Mobilehomes - Permits and Inspections | |

| Northern Region | (916) 225-2501 |

| Southern Region | (916) 782-4420 |

| Employee Housing Standards | (916) 445-9471 |

| Department of Water Resources | |

| Gray Water Installations Standards | (916) 651-9667 |

| Division of the State Architect-Access Compliance | |

| Access Compliance Standards | (916) 445-8100 |

| Division of the State Architect - Structural Safety | |

| Public Schools Standards | (916) 445-8100 |

| Essential Services Building Standards | (916) 445-8100 |

| Community College Standards | (916) 445-8100 |

| Division of the State Architect-State Historical Building Safety Board | |

| Alternative Building Standards | (916) 445-8100 |

| Office of Statewide Health Planning and Development | |

| Hospital Standards | (916) 440-8409 |

| Skilled Nursing Facility Standards | (916) 440-8409 |

| Clinic Standards | (916) 440-8409 |

| Permits | (916) 440-8409 |

| Office of the State Fire Marshal | |

| Code Development and Analysis | (916) 445-8200 |

| Fire Safety Standards | (916) 445-8200 |

| Fireplace Standards | (916) 445-8200 |

| Day-Care Centers Standards | (916) 445-8200 |

| Exit Standards | (916) 445-8200 |

To distinguish between model code language and the incorporated California amendments, including exclusive California standards, California amendments will appear in italics.

[SFM] This symbol within a section identifies which State agency(s), by its “acronym,” has amended a section of the model code.

| BSC | California Building Standards Commission |

| SFM | Office of the State Fire Marshal |

| HCD | Department of Housing and Community Development |

| DSA-AC | Division of the State Architect-Access Compliance |

| DSA-SS | Division of the State Architect-Structural Safety |

| DSA-SS/CC | Division of the State Architect-Structural Safety/Community Colleges |

| OSHPD | Office of Statewide Health Planning and Development |

| CSA | Corrections Standards Authority |

| DPH | Department of Public Health |

| AGR | Department of Food and Agriculture |

| CEC | California Energy Commission |

| CA | Department of Consumer Affairs: |

| Board of Barbering and Cosmetology | |

| Board of Examiners in Veterinary Medicine | |

| Board of Pharmacy | |

| Acupuncture Board | |

| Bureau of Home Furnishings | |

| Structural Pest Control Board | |

| SL | State Librarian |

| SLC | State Lands Commission |

| DWR | Department of Water Resources |

Symbols in the margins indicate the status of code changes as follows:

This symbol indicates that a change has been made to a California amendment.

This symbol indicates California deletion of California language.

Format of the California Matrix Adoption Tables

The matrix adoption tables, which follow, show the user which state agencies have adopted and/or amended given sections of the model code. The building application determines which state agency’s adoptions apply. See Sections 102 through 114 for building applications and enforcement responsibilities.

Agencies are grouped together, based on either local or state enforcement responsibilities. For example, regulations from SFM are enforced both at the state and local levels; therefore, SFM is listed twice in each adoption table indicating state enforcement responsibilities and local enforcement responsibilities.

The side headings identify the scope of state agencies’ adoption as follows:

Adopt the entire IFC chapter without state amendments.

If there is an “X” under a particular state agency’s acronym on this row; this means that particular state agency has adopted the entire model code chapter without any state amendments.

Example:

| Adopting agency | BSC | SFM | HCD | DSA | OSHPD | CSA | DPH | AGR | DWR | CA | SL | SLC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1-AC | AC | SS | SS/CC | 1 | 2 | 3 | 4 | ||||||||||

| Adopt entire chapter | X | ||||||||||||||||||

| Adopt entire chapter as amended (amended sections listed below) | S | A | M | P | L | E | |||||||||||||

| Adopt only those sections that are listed below | |||||||||||||||||||

| Chapter/Section | |||||||||||||||||||

Adopt the entire IFC chapter as amended, state-amended sections are listed below:

If there is an “X” under a particular state agency’s acronym on this row, it means that particular state agency has adopted the entire model code chapter; with state amendments.

Each state-amended section that the agency has added to that particular chapter is listed. There will be an “X” in the column, by that particular section, under the agency’s acronym, as well as an “X” by each section that the agency has adopted.

Example:

| Adopting agency | BSC | SFM | HCD | DSA | OSHPD | CSA | DPH | AGR | DWR | CA | SL | SLC | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 1-AC | AC | SS | SS/CC | 1 | 2 | 3 | 4 | ||||||||||

| Adopt entire chapter | X | ||||||||||||||||||

| Adopt entire chapter as amended (amended sections listed below) | S | A | M | P | L | E | |||||||||||||

| Adopt only those sections that are listed below | |||||||||||||||||||

| Chapter/Section | |||||||||||||||||||

| 202 | X | ||||||||||||||||||

Adopts only those sections that are listed below:

If there is an “X” under a particular state agency’s acronym on this row, it means that particular state agency is adopting only specific model code or state-amended sections within this chapter. There will be an “X” in the column under the agency’s acronym, as well as an “X” by each section that the agency has adopted.

Example:

| Adopting Agency | BSC | DPH | CSA | SL | CA | DWR | AGR | CEC | DSA | HCD | OSHPD | SFM | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AC | SS | SS-CC | 1 | 2 | 1/AC | 1 | 2 | 3 | 4 | ||||||||||

| [BSC] This symbol within a section identifies which State agency(s), by its “acronym,” has amended a section of the model code. | |||||||||||||||||||

| Adopt entire chapter | |||||||||||||||||||

| Adopt entire chapter as amended (amended sections listed below) | S | A | M | P | L | E | |||||||||||||

| Adopt only those sections that are listed below | X | X | |||||||||||||||||

| Chapter 1 | |||||||||||||||||||

| 202 | S | A | M | P | L | E | X | X | |||||||||||

| 202 | C | O | N | T. | X | X | |||||||||||||

| 203 | X | X | |||||||||||||||||

| 203 | X | X | |||||||||||||||||

| BSC | California Building Standards Commission |

| SFM | Office of the State Fire Marshal |

| HCD | Department of Housing and Community Development |

| DSA-AC | Division of the State Architect-Access Compliance |

| DSA-SS | Division of the State Architect-Structural Safety |

| DSA-SS/CC | Division of the State Architect-Structural Safety/Community Colleges |

| OSHPD | Office of Statewide Health Planning and Development |

| CSA | Corrections Standards Authority |

| DPH | Department of Public Health |

| AGR | Department of Food and Agriculture |

| CEC | California Energy Commission |

| CA | Department of Consumer Affairs: |

| Board of Barbering and Cosmetology | |

| Board of Veterinary Medicine Examiners | |

| Board of Pharmacy | |

| Acupuncture Board | |

| Bureau of Home Furnishings | |

| Structural Pest Control Board | |

| SL | State Library |

| SLC | State Lands Commission |

| DWR | Department of Water Resources |

The International Fire Code® (IFC ®) is a model code that regulates minimum fire safety requirements for new and existing buildings, facilities, storage and processes. The IFC addresses fire prevention, fire protection, life safety and safe storage and use of hazardous materials in new and existing buildings, facilities and processes. The IFC provides a total approach of controlling hazards in all buildings and sites, regardless of the hazard being indoors or outdoors.

The IFC is a design document. For example, before one constructs a building, the site must be provided with an adequate water supply for fire-fighting operations and a means of building access for emergency responders in the event of a medical emergency, fire or natural or technological disaster. Depending on the building’s occupancy and uses, the IFC regulates the various hazards that may be housed within the building, including refrigeration systems, application of flammable finishes, fueling of motor vehicles, high-piled combustible storage and the storage and use of hazardous materials. The IFC sets forth minimum requirements for these and other hazards and contains requirements for maintaining the life safety of building occupants, the protection of emergency responders, and to limit the damage to a building and its contents as the result of a fire, explosion or unauthorized hazardous material discharge.

Arrangement and Format of the 2009 IFC

Before applying the requirements of the IFC it is beneficial to understand its arrangement and format. The IFC, like other codes published by the International Code Council, is arranged and organized to follow sequential steps that generally occur during a plan review or inspection. The IFC is divided into eight different parts:

| Chapters | Subjects |

|---|---|

| 1-2 | Administration and definitions |

| 3-4 | General safety requirements |

| 5-10 | Building and site requirements |

| 11-26 and 45 | Special processes and uses |

| 27-44 | Hazardous materials |

| 46 | Construction requirements for existing buildings |

| 47 | Referenced Standards |

| Appendices A-J | Appendices |

The IFC requirements for fire-resistive construction, interior finish, fire protection systems and means of egress are directly correlated to the requirements of the IBC. The following chapters of the IFC are correlated to the IBC:

| Chapter | Subject |

|---|---|

| 7 | Fire-resistance-rated construction |

| 8 | Interior finish, decorative materials and furnishings |

| 9 | Fire protection systems |

| 10 | Means of egress |

The following is a chapter-by-chapter synopsis of the scope and intent of the provisions of the International Fire Code:

Chapter 1 Scope and Administration. This chapter contains provisions for the application, enforcement and administration of subsequent requirements of the code. In addition to establishing the scope of the code, Chapter 1 identifies which buildings and structures come under its purview. Chapter 1 is largely concerned with maintaining “due process of law” in enforcing the regulations contained in the body of the code. Only through careful observation of the administrative provisions can the code official reasonably expect to demonstrate that “equal protection under the law” has been provided.

Chapter 2 Definitions. All terms that are defined in the code are listed alphabetically in Chapter 2. While a defined term may be used in one chapter or another, the meaning provided in Chapter 2 is applicable throughout the code.

Where understanding of a term’s definition is especially key to or necessary for understanding of a particular code provision, the term is show in italics wherever it appears in the code. This is true only for those terms that have a meaning that is unique to the code.

ixIn other words, the generally understood meaning of a term or phrase might not be sufficient or consistent with the meaning prescribed by the code; therefore, it is essential that the code-defined meaning be known.

Guidance regarding tense, gender and plurality of defined terms as well as guidance regarding terms not defined in this code are also provided.

Chapter 3 General Requirements. The open burning, ignition source, vacant building, miscellaneous storage and hazards to fire fighters requirements and precautions, among other general regulations, contained in this chapter are intended to improve premises safety for everyone, including construction workers, tenants, operations and maintenance personnel and emergency response personnel. As with other chapters of the International Fire Code, Section 302 contains definitions applicable to the chapter contents.

Chapter 4 Emergency Planning and Preparedness. This chapter addresses the human contribution to life safety in buildings when a fire or other emergency occurs. The requirements for continuous training and scheduled fire, evacuation and lockdown drills can be as important as the required periodic inspections and maintenance of built-in fire protection features. The level of preparation by the occupants also improves the emergency responder’s abilities during an emergency. The International Building Code® (IBC®) focuses on built-in fire protection features, such as automatic sprinkler systems, fire-resistance-rated construction and properly designed egress systems whereas this chapter fully addresses the human element. As with other chapters of the International Fire Code, Section 402 contains definitions applicable to the chapter contents.

Chapter 5 Fire Service Features. The requirements of this chapter apply to all buildings and occupancies and pertain to access roads; access to building openings and roofs; premises identification; key boxes; fire protection water supplies; fire command centers; fire department access to equipment and emergency responder radio coverage in buildings. As with other chapters of the International Fire Code, Section 502 contains definitions applicable to the chapter contents.

Chapter 6 Building Services and Systems. This chapter focuses on building systems and services as they relate to potential safety hazards and when and how and they should be installed. This chapter brings together all building system-and service-related issues for convenience and provides a more systematic view of buildings. The following buildings services and systems are addressed: fuel-fired appliances (Section 603), emergency and standby power systems (Section 604) electrical equipment, wiring and hazards (Section 605), mechanical refrigeration (Section 606), elevator recall and maintenance (Section 607), stationary storage battery systems (Section 608) and commercial kitchen hoods (Section 609). As with other chapters of the International Fire Code, Section 602 contains definitions applicable to the chapter contents.

Chapter 7 Fire-resistance-rated Construction. The maintenance of assemblies required to be fire-resistance rated is a key component in a passive fire-protection philosophy. Chapter 7 sets forth requirements to maintain required fire-resistance ratings of building elements and limit fire spread. The required maintenance of fire-resistance-rated assemblies and opening protectives is described in Section 703 while Section 704 covers the enclosure requirements for shafts in existing buildings. As with other chapters of the International Fire Code, Section 702 contains definitions applicable to the chapter contents.

Chapter 8 Interior Finish, Decorative Materials and Furnishings. The overall purpose of Chapter 8 is to regulate interior finishes, decorative materials and furnishings in new and existing buildings so that they do not significantly add to or create fire hazards within buildings. The provisions tend to focus on occupancies with specific risk characteristics, such as vulnerability of occupants, density of occupants, lack of familiarity with the building and societal expectations of importance. This chapter is consistent with Chapter 8 of the International Building Code® (IBC®), which regulates the interior finishes of new buildings. As with other chapters of the International Fire Code, Section 802 contains definitions applicable to the chapter contents.

Chapter 9 Fire Protection Systems. Chapter 9 prescribes the minimum requirements for active systems of fire protection equipment to perform the functions of detecting a fire, alerting the occupants or fire department of a fire emergency, controlling smoke and controlling or extinguishing the fire. Generally, the requirements are based on the occupancy, the height and the area of the building, because these are the factors that most affect fire-fighting capabilities and the relative hazard of a specific building or portion thereof. This chapter parallels and is substantially duplicated in Chapter 9 of the International Building Code: however, this chapter also contains periodic testing criteria that are not contained in the IBC. In addition, the special fire protection system requirements based on use and occupancy found in Chapter 4 of the IBC are duplicated in Chapter 9 of the IFC as a user convenience. As with other chapters of the International Fire Code, Section 902 contains definitions applicable to the chapter contents.

Chapter 10 Means of Egress. The general criteria set forth in Chapter 10 regulating the design of the means of egress are established as the primary method for protection of people in buildings by allowing timely relocation or evacuation of building occupants. Both prescriptive and performance language is utilized in this chapter to provide for a basic approach in the determination of a safe existing system for all occupancies. It addresses all portions of the egress system (i.e., exit access, exits and exit discharge) and includes design requirements as well as provisions regulating individual components. The requirements detail the size, arrangement, number and protection of means of egress components. Functional and operational characteristics also are specified for the components that will permit their safe use without special knowledge or effort. The means of egress protection requirements work in coordination with other sections of the code, such as protection of vertical openings (see Chapter 7), interior finish (see Chapter 8), fire suppression and detection systems (see Chapter 9) and numerous others, all having an impact on life safety. Sections 1002 through 1029 are duplicated text from Chapter 10 of the IBC; however, the IFC contains an additional Section 1030 on maintenance of the means of egress system in

xexisting buildings. Retroactive minimum means of egress requirements for existing buildings are now found in Chapter 46. As with other chapters of the International Fire Code, Section 1002 contains definitions applicable to the chapter contents.

Chapter 11 Aviation Facilities. Chapter 11 specifies minimum requirements for the fire-safe operation of airports, heliports and helistops. The principal nonflight operational hazards associated with aviation involve fuel, facilities and operations. Therefore, safe use of flammable and combustible liquids during fueling and maintenance operations is emphasized. Availability of portable Class B:C-rated fire extinguishers for prompt control or suppression of incipient fires is required. As with other chapters of the International Fire Code, Section 1102 contains definitions applicable to the chapter contents.

Chapter 12 Dry Cleaning. The provisions of Chapter 12 are intended to reduce hazards associated with use of flammable and combustible dry cleaning solvents. These materials, like all volatile organic chemicals, generate significant quantities of static electricity and are thus readily ignitable. Many flammable and nonflammable dry cleaning solvents also possess health hazards when involved in a fire. As with other chapters of the International Fire Code, Section 1202 contains definitions applicable to the chapter contents.

Chapter 13 Combustible Dust-producing Operations. The requirements of Chapter 13 seek to reduce the likelihood of dust explosions by managing the hazards of ignitable suspensions of combustible dusts associated with a variety of operations including woodworking, mining, food processing, agricultural commodity storage and handling and pharmaceutical manufacturing, among others. Ignition source control and good housekeeping practices in occupancies containing dust-producing operations are emphasized. As with other chapters of the International Fire Code, Section 1302 contains a definition applicable to the chapter contents.

Chapter 14 Fire Safety During Construction and Demolition. This chapter outlines general fire safety precautions for all structures and all occupancies during construction and demolition operations. In general, these requirements seek to maintain required levels of fire protection, limit fire spread, establish the appropriate operation of equipment and promote prompt response to fire emergencies. Features regulated include fire protection systems, fire fighter access to the site and building, means of egress, hazardous materials storage and use and temporary heating equipment and other ignition sources.

Chapter 15 Flammable Finishes. Chapter 15 requirements govern operations where flammable or combustible finishes are applied by spraying, dipping, powder coating or flow-coating processes. As with all operations involving flammable or combustible liquids and combustible dusts or vapors, controlling ignition sources and methods of reducing or controlling flammable vapors or combustible dusts at or near these operations are emphasized. As with other chapters of the International Fire Code, Section 1502 contains definitions applicable to the chapter contents.

Chapter 16 Fruit and Crop Ripening. Chapter 16 provides guidance that is intended to reduce the likelihood of explosions resulting from improper use or handling of ethylene gas used for crop-ripening and coloring processes. This is accomplished by regulating ethylene gas generation; storage and distribution systems and controlling ignition sources. Design and construction of facilities for this use are regulated by the International Building Code to reduce the impact of potential accidents on people and buildings.

Chapter 17 Fumigation and Thermal Insecticidal Fogging. This chapter regulates fumigation and thermal insecticidal fogging operations which use toxic pesticide chemicals to kill insects, rodents and other vermin. Fumigants and thermal insecticidal fogging agents pose little hazard if properly applied; however, the inherent toxicity of all these agents and the potential flammability of some makes special precautions necessary when they are used. Requirements of this chapter are intended to protect both the public and fire fighters from hazards associated with these products. As with other chapters of the International Fire Code, Section 1702 contains definitions applicable to the chapter contents.

Chapter 18 Semiconductor Fabrication Facilities. The requirements of this chapter are intended to control hazards associated with the manufacture of electrical circuit boards or microchips, commonly called semiconductors. Though the finished product possesses no unusual hazards, materials commonly associated with semiconductor manufacturing are often quite hazardous and include flammable liquids; pyrophoric and flammable gases; toxic substances and corrosives. The requirements of this chapter are concerned with both life safety and property protection. However, the fire code official should recognize that the risk of extraordinary property damages is far more common than the risk of personal injuries from fire. As with other chapters of the International Fire Code, Section 1802 contains definitions applicable to the chapter contents.

Chapter 19 Lumber Yards and Woodworking Facilities. Provisions of this chapter are intended to prevent fires and explosions, facilitate fire control and reduce exposures to and from facilities storing, selling or processing wood and forest products, including sawdust, wood chips, shavings, bark mulch, shorts, finished planks, sheets, posts, poles, timber and raw logs and the hazard they represent once ignited. This chapter requires active and passive fire protection features to reduce on- and off-site exposures, limit fire size and development and facilitate fire fighting by employees and the fire service. As with other chapters of the International Fire Code, Section 1902 contains definitions applicable to the chapter contents.

Chapter 20 Manufacture of Organic Coatings. This chapter regulates materials and processes associated with the manufacture of paints as well as bituminous, asphaltic and other diverse compounds formulated to protect buildings, machines and objects from the effects of weather, corrosion and hostile environmental exposures. Paint for decorative, architectural and industrial uses comprises the bulk of organic coating production. Painting and processes related to the manufacture of nonflammable and noncombustible or water-based products are exempt from the provisions of this chapter. The application of organic coatings is covered by Chapter 15. Elimination of ignition sources, maintenance of fire protection equipment and isolation or segregation of hazardous operations are

xiemphasized. As with other chapters of the International Fire Code, Section 2002 contains a definition applicable to the chapter contents.

Chapter 21 Industrial Ovens. This chapter addresses the fuel supply, ventilation, emergency shutdown equipment, fire protection and the operation and maintenance of industrial ovens, which are sometimes referred to as industrial heat enclosures or industrial furnaces. Compliance with this chapter is intended to reduce the likelihood of fires involving industrial ovens which are usually the result of the fuel in use or volatile vapors given off by the materials being heated or to manage the impact if a fire should occur. As with other chapters of the International Fire Code, Section 2102 contains definitions applicable to the chapter contents.

Chapter 22 Motor Fuel-dispensing Facilities and Repair Garages. This chapter provides provisions that regulate the storage and dispensing of both liquid and gaseous motor fuels at public and private automotive, marine and aircraft motor fuel-dispensing facilities, fleet vehicle motor fuel-dispensing facilities and repair garages. As with other chapters of the International Fire Code, Section 2202 contains definitions applicable to the chapter contents.

Chapter 23 High-piled Combustible Storage. This chapter provides guidance for reasonable protection of life from hazards associated with the storage of combustible materials in closely packed piles or on pallets, in racks or on shelves where the top of storage is greater than 12 feet in height. It provides requirements for identifying various classes of commodities; general fire and life safety features including storage arrangements, smoke and heat venting, fire department access and housekeeping and maintenance requirements. The chapter attempts to define the potential fire severity and, in turn, determine fire and life safety protection measures needed to control, and in some cases suppress, a potential fire. This chapter does not cover miscellaneous combustible materials storage regulated in Section 315. As with other chapters of the International Fire Code, Section 2302 contains definitions applicable to the chapter contents.

Chapter 24 Tents and Other Membrane Structures. The requirements in this chapter are intended to protect temporary as well as permanent tents and air-supported and other membrane structures from fire by regulating structure location and access, anchorage, egress, heat-producing equipment, hazardous materials and operations, combustible vegetation, ignition sources, waste accumulation and requiring regular inspections and certifying continued compliance with fire safety regulations. As with other chapters of the International Fire Code, Section 2402 contains definitions applicable to the chapter contents.

Chapter 25 Tire Rebuilding and Tire Storage. The requirements of Chapter 25 are intended to prevent or control fires and explosions associated with the remanufacture and storage of tires and tire by-products. Additionally, the requirements are intended to minimize the impact of indoor and outdoor tire storage fires by regulating pile volume and location, segregating the various operations, providing for fire department access and a water supply and controlling ignition sources.

Chapter 26 Welding and Other Hot Work. This chapter covers requirements for safety in welding and other types of hot work by reducing the potential for fire ignitions that usually result in large losses. Several different types of hot work would fall under the requirements found in Chapter 26, including both gas and electric are methods and any open-torch operations. Many of the activities of this chapter focus on the actions of the occupants. As with other chapters of the International Fire Code, Section 2602 contains definitions applicable to the chapter contents.

Chapter 27 Hazardous Materials—General Provisions. This chapter contains the general requirements for all hazardous chemicals in all occupancies. Hazardous chemicals are defined as those that pose an unreasonable risk to the health and safety of operating or emergency personnel, the public and the environmental if not properly controlled during handling, storage, manufacture, processing, packaging, use, disposal or transportation. The general provisions of this chapter are intended to be companion provisions with the specific requirements of Chapters 28 through 44 regarding a given hazardous material. As with other chapters of the International Fire Code, Section 2702 contains definitions applicable to the chapter contents.

Chapter 28 Aerosols. Chapter 28 addresses the prevention, control and extinguishment of fires and explosions in facilities where retail aerosol products are displayed or stored. It is concerned with both life safety and property protection from a fire; however, historically, aerosol product fires have caused property loss more frequently than loss of life. Requirements for storing aerosol products are dependent on the level of aerosol product, level of sprinkler protection, type of storage condition and quantity of aerosol products. As with other chapters of the International Fire Code, Section 2802 contains definitions applicable to the chapter contents.

Chapter 29 Combustible Fibers. Chapter 29 established the requirements for storage and handling of combustible fibers, including animal, vegetable and synthetic fibers, Whether woven into textiles, baled, packaged or loose. Operations involving combustible fibers are typically associated with salvage, paper milling, recycling, cloth manufacturing, carpet and textile mills and agricultural operations, among others.

The primary hazard associated with these operations is the abundance of materials and their ready ignitability. As with other chapters of the International Fire Code, Section 2902 contains definitions applicable to the chapter contents.

Chapter 30 Compressed Gases. This chapter regulates the storage, use and handling of all flammable and nonflammable compressed gases, such as those that are used in medical facilities, air separation plants, industrial plants, agricultural equipment and similar occupancies. Standards for the design, construction and marking of compressed gas cylinders and pressure vessels are referenced. Compressed gases used in welding and cutting, cryogenic liquids and liquefied petroleum gases are also regulated under Chapters 26, 32 and 38, respectively. Compressed gases that are classified as hazardous materials are also regulated in Chapter 27.

xiiwhich includes general requirements. As with other chapters of the International Fire Code, Section 3002 contains definitions applicable to the chapter contents.

Chapter 31 Corrosive Materials. Chapter 31 addresses the hazards of corrosive materials that have a destructive effect on living tissues. Though corrosive gases exist, most corrosive materials are solid and classified as either acids or bases (alkalis). These materials may pose a wide range of hazards other than corrosivity, such as combustibility, reactivity or oxidizing hazards, and must conform to the requirements of the code with respect to all their known hazards. The focus of this chapter is on materials whose primary hazard is corrosivity; that is, the ability to destroy or irreparably damage living tissue on contact. As with other chapters of the International Fire Code, Section 3102 contains a definition applicable to the chapter contents.

Chapter 32 Cryogenic Fluids. This chapter regulates the hazards associated with the storage, use and handling of cryogenic fluids through regulation of such things as pressure relief mechanisms and proper container storage. These hazards are in addition to the code requirements that address the other hazards of cryogenic fluids such as flammability and toxicity. These other characteristics are dealt with in Chapter 27 and other chapters, such as Chapter 35 dealing with flammable gases. Cryogens are hazardous because they are held at extremely low temperatures and high pressures. Many cryogenic fluids, however, are actually inert gases and would not be regulated elsewhere in the code. Cryogens are used for many applications but specifically have had widespread use in the biomedical field and in space programs. As with other chapters of the International Fire Code, Section 3202 contains definitions applicable to the chapter contents.

Chapter 33 Explosives and Fireworks. Reserved.

Chapter 34 Flammable and Combustible Liquids. The requirements of this chapter are intended to reduce the likelihood of fires involving the storage, handling, use or transportation of flammable and combustible liquids. Adherence to these practices may also limit damage in the event of an accidental fire involving these materials. These liquids are used for fuel, lubricants, cleaners, solvents, medicine and even drinking. The danger associated with flammable and combustible liquids is that the vapors from these liquids, when combined with air in their flammable range, will burn or explode at temperatures near our normal living and working environment. The protection provided by the code is to prevent the flammable and combustible liquids from being ignited. As with other chapters of the International Fire Code, Section 3402 contains definitions applicable to the chapter contents.

Chapter 35 Flammable Gases and Flammable Cryogenic Fluids. Chapter 35 sets requirements for the storage and use of flammable gases. For safety purposes, there is a limit on the quantities of flammable gas allowed per control area. Exceeding these limitations increases the possibility of damage to both property and individuals. The principal hazard posed by flammable gas is its ready ignitability, or even explosivity, when mixed with air in the proper proportions. Consequently, occupancies storing or handling large quantities of flammable gas are classified as Group H-2 (high hazard) by the International Building Code. As with other chapters of the International Fire Code, Section 3502 contains definitions applicable to the chapter contents.

Chapter 36 Flammable Solids. This chapter addresses general requirements for storage and handling of flammable solids, especially magnesium; however, it is important to note that several other solid materials, primarily metals including, but not limited to, such metals as titanium, zirconium, hafnium, calcium, zinc, sodium, lithium, potassium, sodium/potassium alloys, uranium, thorium, and plutonium which, under the right conditions, can be explosion hazards. Some of these metals are almost exclusively laboratory materials but because of where they are used, fire service personnel must be trained to handle emergency situations. Because uranium, thorium and plutonium are also radioactive materials, they present still more specialized problems for fire service personnel. As with other chapters of the International Fire Code, Section 3602 contains definitions applicable to the chapter contents.

Chapter 37 Highly Toxic and Toxic Materials. The main purpose of this chapter is to protect occupants, emergency responders and those in the immediate area of the building and facility from short-term, acute hazards associated with a release or general exposure to toxic and highly toxic materials. This chapter deals with all three states of toxic and highly toxic materials: solids, liquids and gases. The code does not address long-term exposure effects of these materials which are addressed by agencies such as the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA). As with other chapters of the International Fire Code, Section 3702 contains definitions applicable to the chapter contents.

Chapter 38 Liquefied Petroleum Gases. Chapter 38 establishes requirements for the safe handling, storing and use of LP-gas to reduce the possibility of damage to containers, accidental releases of LP-gas and exposure of flammable concentrations of LP-gas to ignition sources. LP-gas (notably Propane) is well known as a camping fuel for cooking, lighting, heating and refrigerating and also remains a popular standby fuel supply for auxiliary generators as well as being widely used as an alternative motor vehicle fuel. Its characteristic as a clean-burning fuel having resulted in the addition of propane dispensers to service stations throughout the country. As with other chapters of the International Fire Code, Section 3802 contains a definition applicable to the chapter contents.

Chapter 39 Organic Peroxides. This chapter addresses the hazards associated with the storage, handling and use of organic peroxides and intends to manage the fire and oxidation hazards of organic peroxides by preventing their uncontrolled release. These chemicals posses the characteristics of flammable or combustible liquids and are also strong oxidizers. This unusual combination of properties requires special storage and handling precautions to prevent uncontrolled release, contamination, hazardous chemical reaction, fires or explosions. The requirements of this chapter pertain to industrial applications in which significant quantities of organic peroxides are stored or used; however, smaller quantities of organic peroxides still pose a significant hazard and, therefore, must be stored and used in accordance with the applicable provisions of this chapter and Chapter 27. As with other chapters of the International Fire Code, Section 3902 contains a definition applicable to the chapter contents.

xiiiChapter 40 Oxidizers, Oxidizing Gases and Oxidizing Cryogenic Fluids. Chapter 40 addresses the hazards associated with solid, liquid, gaseous and cryogenic fluid oxidizing materials, including oxygen in home use, and establishes criteria for their safe storage and protection in indoor and outdoor storage facilities, minimizing the potential for uncontrolled releases and contact with fuel sources. Although oxidizers themselves do not burn, they pose unique fire hazards because of their ability to support combustion by breaking down and giving off oxygen. As with other chapters of the International Fire Code, Section 4002 contains definitions applicable to the chapter contents.

Chapter 41 Pyrophoric Materials. This chapter regulates the hazards associated with pyrophoric materials, which are capable of spontaneously igniting in the air at or below a temperature of 130°F (54°C). Many pyrophoric materials also pose severe flammability or reactivity hazards. This chapter addresses only the hazards associated with pyrophoric material. Materials the that pose multiple hazards must conform to the requirements of the code with respect to all hazards. As with other chapters of the International Fire Code, Section 4102 contains a definition applicable to the chapter contents.

Chapter 42 Pyroxylin (Cellulose Nitrate) Plastics. This chapter addresses the significant hazards associated with pyroxylin (cellulose nitrate) plastics, which are the most dangerous and unstable of all plastic compounds. The chemically bound oxygen in their structure permits them to burn vigorously in the absence of atmospheric oxygen at a rate 15 times greater than comparable common combustibles. Strict compliance with the provisions of this chapter, along with proper housekeeping and storage arrangements, help to reduce the hazards associated with pyroxylin (cellulose nitrate) plastics in a fire or other emergencies.

Chapter 43 Unstable (Reactive) Materials. This chapter addresses the hazards of unstable (reactive) liquid and solid materials as well as unstable (reactive) compressed gases. In addition to their unstable reactivity, these materials may pose other hazards, such as toxicity, corrosivity, explosivity, flammability or oxidizing potential. This chapter, however, intends to address those materials whose primary hazard is reactivity. Materials that pose multiple hazards must conform to the requirements of the code with respect to all hazards. Strict compliance with the provisions of this chapter, along with proper housekeeping and storage arrangements, help to reduce the exposure hazards associated with unstable (reactive) materials in a fire or other emergency. As with other chapters of the International Fire Code, Section 4302 contains a definition applicable to the chapter contents.

Chapter 44 Water-reactive Solids and Liquids. This chapter addresses the hazards associated with water-reactive materials that are solid or liquid at normal temperatures and pressures. In addition to their water reactivity, these materials may pose a wide range of other hazards, such as toxicity, flammability, corrosiveness or oxidizing potential. This chapter addresses only those materials whose primary hazard is water reactivity. Materials that pose multiple hazards must conform to the requirements of the code with respect to all hazards. Strict compliance with the requirements of this chapter, along with proper housekeeping and storage arrangements, help to reduce the exposure hazards associated with water-reactive materials in a fire or other emergency. As with other chapters of the International Fire Code, Section 4402 contains a definition applicable to the chapter contents.

Chapter 45 Marinas. Chapter 45 is a new chapter in the 2009 International Fire Code addressing the fire protection and prevention requirements for marinas. It was developed in response to the complications encountered by a number of fire departments responsible for the protection of marinas as well as fire loss history in marinas that lacked fire protection. Compliance with this chapter intends to establish safe practices in marina areas, provide an identification method for mooring spaces in the marina, provide fire fighters with safe operational areas and fire protection methods to extend hose lines in a safe manner. As with other chapters of the International Fire Code, Section 4502 contains definitions applicable to the chapter contents.

Chapter 46 Construction Requirements for Existing Buildings. Chapter 46 is also a new chapter in the 2009 International Fire Code. This chapter applies to existing buildings constructed prior to the adoption of this code and intends to provide a minimum degree of fire and life safety to persons occupying existing buildings by providing for alterations to such buildings that do not comply with the minimum requirements of the International Building Code. While this chapter is new, its content existed previously in the IFC but in a random manner that was neither efficient nor user-friendly. In the 2007/2008 code development cycle, code change F294-07/08 was approved that consolidated the retroactive elements of IFC/2006 Sections 607, 701, 704, 903, 905, 907 and 2506 and all of Section 1027 into a single chapter for easier and more efficient reference and application to existing buildings. As with other chapters of the International Fire Code, Section 4602 contains definitions applicable to the chapter contents.

Chapter 47 Referenced Standards. The code contains several references to standards that are used to regulate materials and methods of construction. Chapter 47 contains a comprehensive list of all standards that are referenced in the code. The standards are part of the code to the extent of the reference to the standard. Compliance with the referenced standard is necessary for compliance with this code. By providing specifically adopted standards, the construction and installation requirements necessary for compliance with the code can be readily determined. The basis for code compliance is, therefore, established and available on an equal basis to the code official, contractor, designer and owner.

Chapter 47 is organized in a manner that makes it easy to locate specific standards. It lists all of the referenced standards, alphabetically, by acronym of the promulgating agency of the standard. Each agency's standards are then listed in either alphabetical or numeric order based upon the standard identification. The list also contains the title of the standard; the edition (date) of the standard referenced; any addenda included as part of the ICC adoption; and the section or sections of this code that reference the standard.

Appendix A Board of Appeals. This appendix contains optional criteria that, when adopted, provides jurisdictions with detailed appeals, board member qualifications and administrative procedures to supplement the basic requirements found in Section 108 of

xivthe code. Note that the provisions contained in this appendix are not mandatory unless specifically referenced in the adopting ordinance (see sample ordinance on page xiii).

Appendix B Fire-flow Requirements for Buildings. This appendix provides a tool for the use of jurisdictions in establishing a policy for determining fire-flow requirements in accordance with IFC Section 507.3. The determination of required fire flow is not an exact science, but having some level of information provides a consistent way of choosing the appropriate fire flow for buildings throughout a jurisdiction. The primary tool used in this appendix is a table which presents fire flows based on construction type and building area based on the correlation of the Insurance Services Office (ISO) method and the construction types used in the International Building Code. Note that the provisions contained in this appendix are not mandatory unless specifically referenced in the adopting ordinance (see sample ordinance on page xiii).

Appendix C Fire Hydrant Locations and Distribution. This appendix focuses on the location and spacing of fire hydrants which are important to the success of fire-fighting operation. The difficulty with determining the spacing of fire hydrants is that every situation is unique and has unique challenges. Finding one methodology for determining hydrant spacing is difficult. This particular appendix gives one methodology based on the required fire flow that fire departments can work with to set a policy for hydrant distribution around new buildings and facilities in conjunction with IFC Section 507.5. Note that the provisions contained in this appendix are not mandatory unless specifically referenced in the adopting ordinance (see sample ordinance on page xiii).

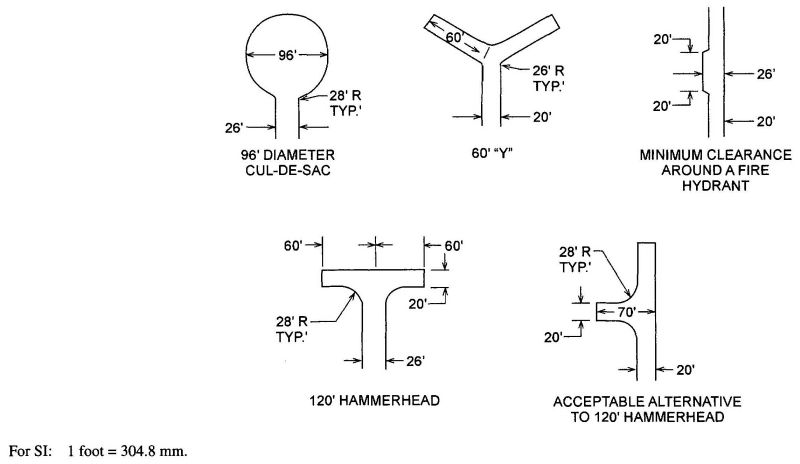

Appendix D Fire Apparatus Access Roads. This appendix contains more detailed elements for use with the basic access requirements found in IFC Section 503 which gives some minimum criteria, such as a maximum length of 150 feet and a minimum width of 20 feet, but in many cases does not state specific criteria. This appendix, like Appendices B and C, is a tool for jurisdictions looking for guidance in establishing access requirements and includes criteria for multiple-family residential developments, large one- and two-family subdivisions, specific examples for various types of turnarounds for fire department apparatus and parking regulatory signage. Note that the provisions contained in this appendix are not mandatory unless specifically referenced in the adopting ordinance (see sample ordinance on page xiii).

Appendix E Hazard Categories. This appendix contains guidance for designers, engineers, architects, code officials, plans reviewers and inspectors in the classifying if hazardous materials so that proposed designs can be evaluated intelligently and accurately. The descriptive materials and explanations of hazardous materials and how to report and evaluate them on a Material Safety Data Sheet that are contained in this appendix are intended to be instructional as well as informative. Note that this appendix is for information purposes and is not intended for adoption.

Appendix F Hazard Ranking. The information in this appendix is intended to be a companion to the specific requirements of Chapters 28 through 44 which regulate the storage, handling and use of all hazardous materials classified as either physical or health hazards. These materials pose diverse hazards, including instability, reactivity, flammability, oxidizing potential or toxicity; therefore, identifying them by hazard ranking is essential. This appendix lists the various hazardous materials categories that are defined in the code, along with the NFPA 704 hazard ranking for each. Note that the provisions contained in this appendix are not mandatory unless specifically referenced in the adopting ordinance (see sample ordinance on page xiii).

Appendix G Cryogenic Fluids—Weight and Volume Equivalents. This appendix gives the fire code official and design professional a ready reference tool for the conversion of the liquid weight and volume of cryogenic fluid to their corresponding volume of gas and vice versa and is a companion to the provisions of Chapter 32 of the code. Note that this appendix is for information purposes and is not intended for adoption.

Appendix H Hazardous Materials Management Plan (HMMP) and Hazardous Materials Inventory Statement (HMIS) Instructions. This new IFC appendix is intended to assist businesses in establishing a Hazardous Materials Management Plan (HMMP) and Hazardous Materials Inventory Statement (HMIS) based on the classification and quantities of materials that would be found on site in storage and/or use. The sample forms and available Material Safety Data sheets (MSDS) provide the basis for the evaluations. It is also a companion to IFC Sections 407.5 and 407.6 which provide the requirement that the HMIS and HMMP be submitted when required by the fire code official. Note that the provisions contained in this appendix are not mandatory unless specifically referenced in the adopting ordinance (see sample ordinance on page xiii).

Appendix I Fire Protections Systems—Unsafe Conditions. The purpose of this new IFC appendix, which was developed by the ICC Hazard Abatement in Existing Buildings Committee, is to provide the fire code official with a list of conditions that are readily identifiable by the inspector during the course of an inspection utilizing the International Fire Code. The specific conditions identified in this appendix are primarily derived from applicable NFPA standards and pose a hazard to the proper operation of the respective systems. While these do not represent all of the conditions that pose a hazard or otherwise may impair the proper operation of fire protection systems, their identification in this adoptable appendix will provide a more direct path for enforcement by the fire code official. Note that the provisions contained in this appendix are not mandatory unless specifically referenced in the adopting ordinance (see sample ordinance on page xiii).

Appendix J Emergency Responder Radio Coverage. This new IFC Appendix provides design, installation, testing and maintenance requirements for the emergency responder communications facilities where required by new IFC Sections 510. Included are requirements for system performance, primary and secondary power supplies, signal boosters, radio frequencies, installer qualifications, acceptance testing and system maintenance. Note that the provisions contained in this appendix are not mandatory unless specifically referenced in the adopting ordinance (see sample ordinance on page xiii).

xv xviThe International Codes are designed and promulgated to be adopted by reference by ordinance. Jurisdictions wishing to adopt the 2010 California Fire Code as an enforceable set of regulations for the safeguarding of life and property from fire and explosion hazards arising from the storage, handling and use of hazardous substances, materials and devices, and from conditions hazardous to life or property in the occupancy of buildings and permises should ensure that certain factual information is included in the adopting ordinance at the time adoption is being considered by the appropriate government body. The following sample adoption ordinance addresses several key elements of a code adoption ordinance, including the information required for insertion into the code text.

An ordinance of the [NAME OF JURISDICTION] adopting the 2010 edition of the California Fire Code, regulating and governing the safeguarding of life and property from fire and explosion hazards arising from the storage, handling and use of hazardous substances, materials and devices, and from conditions hazardous to life or property in the occupancy of buildings and premises in the [NAME OF JURISDICTION]; providing for the issuance of permits and collection of fees therefor; repealing Ordinance No.— of the [NAME OF JURISDICTION] and all other ordinances and parts of the ordinances in conflict therewith.

The [GOVERNING BODY] of the [NAME OF JURISDICTION] does ordain as follows:

Section 1. That a certain document, three (3) copies of which are on file in the office of the [TITLE OF JURISDICTION'S KEEPER OF RECORDS] of [NAME OF JURISDICTION], being marked and designated as the California Fire Code, 2010 edition, including Appendix Chapters [FILL IN THE APPENDIX CHAPTERS BEING ADOPTED] (see California Fire Code Section 101.2.1, 2010 edition), as published by the International Code Council, be and is hereby adopted as the Fire Code of the [NAME OF JURISDICTION], in the State of California regulating and governing the safeguarding of life and property from fire and explosion hazards arising from the storage, handling and use of hazardous substances, materials and devices, and from conditions hazardous to life or property in the occupancy of buildings and premises as herein provided; providing for the issuance of permits and collection of fees therefor; and each and all of the regulations, provisions, penalties, conditions and terms of said Fire Code on file in the office of the [NAME OF JURISDICTION] are hereby referred to, adopted, and made a part hereof, as if fully set out in this ordinance, with the additions, insertions, deletions and changes, if any, prescribed in Section 2 of this ordinance.

Section 2. That the following sections are hereby revised:

Section 101.1. Insert: [NAME OF JURISDICTION]

Section 109.3. Insert: [OFFENSE, DOLLAR AMOUNT, NUMBER OF DAYS]

Section 111.4. Insert: [DOLLAR AMOUNT IN TWO LOCATIONS]

Section 3. That the geographic limits referred to in certain sections of the 2009 California Fire Code are hereby established as follows:

Section 3404.2.9.6.1 (geographic limits in which the storage of Class I and Class II liquids in above-ground tanks outside of buildings is prohibited): [JURISDICTION TO SPECIFY]

Section 3406.2.4.4 (geographic limits in which the storage of Class I and Class II liquids in above-ground tanks is prohibited):[JURISDICTION TO SPECIFY]

Section 3506.2 (geographic limits in which the storage of flammable cryogenic fluids in stationary containers is prohibited): [JURISDICTION TO SPECIFY]

Section 3804.2 (geographic limits in which the storage of liquefied petroleum gas is restricted for the protection of heavily populated or congested areas): [JURISDICTION TO SPECIFY]

Section 4. That Ordinance No.______ of [NAME OF JURISDICTION] entitled [FILL IN HERE THE COMPLETE TITLE OF THE ORDINANCE OR ORDINANCES IN EFFECT AT THE PRESENT TIME SO THAT THEY WILL BE REPEALED BY SPECIFIC REFERENCE] and all other ordinances or parts of ordinances in conflict herewith are hereby repealed.

Section 5. That if any section, subsection, sentence, clause or phrase of this ordinance is, for any reason, held to be unconstitutional, such decision shall not affect the validity of the remaining portions of this ordinance. The [GOVERNING BODY] hereby declares that it would have passed this ordinance, and each section, subsection, clause or phrase thereof, irrespective of the fact that any one or more sections, subsections, sentences, clauses and phrases be declared unconstitutional.

xviiSection 6. That nothing in this ordinance or in the Fire Code hereby adopted shall be construed to affect any suit or proceeding impending in any court, or any rights acquired, or liability incurred, or any cause or causes of action acquired or existing, under any act or ordinance hereby repealed as cited in Section 4 of this ordinance; nor shall any just or legal right or remedy of any character be lost, impaired or affected by this ordinance.

Section 7. That the [JURISDICTION'S KEEPER OF RECORDS] is hereby ordered and directed to cause this ordinance to be published. (An additional provision may be required to direct the number of times the ordinance is to be published and to specify that it is to be in a newspaper in general circulation. Posting may also be required.)

Section 8. That this ordinance and the rules, regulations, provisions, requirements, orders and matters established and adopted hereby shall take effect and be in full force and effect [TIME PERIOD] from and after the date of its final passage and adoption.

xviii| CHAPTER I SCOPE AND ADMINISTRATION | 3 | |

| DIVISION I—CALIFORNIA ADMINISTRATION | 3 | |

| Section | ||

| 1.1 | General | 3 |

| 1.11 | Office of the State Fire Marshal | 5 |

| DIVISION II—ADMINISTRATION | 10 | |

| PART 1— GENERAL PROVISIONS | 10 | |

| Section | ||

| 101 | General | 10 |

| 102 | Applicability | 10 |

| PART 2—ADMINISTRATIVE PROVISIONS | 11 | |

| 103 | Department of Fire Prevention | 11 |

| 104 | General Authority and Responsibilities | 11 |

| 105 | Permits | 13 |

| 106 | Inspections | 20 |

| 107 | Maintenance | 20 |

| 108 | Board of Appeals | 20 |

| 109 | Violations | 21 |

| 110 | Unsafe Buildings | 21 |

| 111 | Stop Work Order | 22 |

| 112 | Service Utilities | 22 |

| 113 | Fees | 22 |

| CHAPTER 2 DEFINITIONS | 25 | |

| Section | ||

| 201 | General | 25 |

| 202 | General Definitions | 25 |

| CHAPTER 3 GENERAL PRECAUTIONS AGAINST FIRE | 49 | |

| Section | ||

| 301 | General | 49 |

| 302 | Definitions | 49 |

| 303 | Asphalt Kettles | 50 |

| 304 | Combustible Waste Material | 50 |

| 305 | Ignition Sources | 52 |

| 306 | Motion Picture Projection Rooms and Film | 52 |

| 307 | Open Burning, Recreational Fires and Portable Outdoor Fireplaces | 52 |

| 308 | Open Flames | 53 |

| 309 | Powered Industrial Trucks and Equipment | 55 |

| 310 | Smoking | 55 |

| 311 | Vacant Premises | 56 |

| 312 | Vehicle Impact Protection | 57 |

| 313 | Fueled Equipment | 57 |

| 314 | Indoor Displays | 57 |

| 315 | Miscellaneous Combustible Materials Storage | 57 |

| 316 | Hazards to Fire Fighters | 58 |

| 317 | Laundry Carts | 58 |

| CHAPTER 4 EMERGENCY PLANNING AND PREPAREDNESS | 61 | |

| Section | ||

| 401 | General | 61 |

| 402 | Definitions | 61 |

| 403 | Public Assemblages and Events | 61 |

| 404 | Fire Safety and Evacuation Plans | 62 |

| 405 | Emergency Evacuation Drills | 65 |

| 406 | Employee Training and Response Procedures | 66 |

| 407 | Hazard Communication | 66 |

| 408 | Use and Occupancy-Related Requirements | 67 |

| CHAPTER 5 FIRE SERVICE FEATURES | 73 | |

| Section | ||

| 501 | General | 73 |

| 502 | Definitions | 73 |

| 503 | Fire Apparatus Access Roads | 73 |

| 504 | Access to Building Openings and Roofs | 74 |

| 505 | Premises Identification | 75 |

| 506 | Key Boxes | 75 |

| 507 | Fire Protection Water Supplies | 75 |

| 508 | Fire Command Center | 76 |

| 509 | Fire Protection Equipment Identification and Access | 76 |

| 510 | Emergency Responder Radio Coverage | 77 |

| CHAPTER 6 BUILDING SERVICES AND SYSTEMS | 81 | |

| Section | ||

| 601 | General | 81 |

| 602 | Definitions | 81 |

| 603 | Fuel-fired Appliances | 82 |

| 604 | Emergency and Standby Power Systems | 84 |

| 605 | Electrical Equipment, Wiring and Hazards | 87 |

| 606 | Mechanical Refrigeration | 88 |

| 607 | Elevator Recall and Maintenance | 90 |

| 608 | Stationary Storage Battery Systems | 90 |

| 609 | Commercial Kitchen Hoods | 92 |

| CHAPTER 7 FIRE-RESISTANCE-RATED CONSTRUCTION | 95 | |

| Section | ||

| 701 | General | 95 |

| 702 | Definitions | 95 |

| 703 | Fire-Resistance-Rated Construction | 95 |

| 704 | Floor Openings and Shafts | 96 |

| CHAPTER 8 INTERIOR FINISH, DECORATIVE MATERIALS AND FURNISHINGS | 99 | |

| Section | ||

| 801 | General | 99 |

| 802 | Definitions | 99 |

| 803 | Interior Wall and Ceiling Finish and Trim in Existing Buildings | 100 |

| 804 | Interior Wall and Ceiling Trim in New and Existing Buildings | 102 |

| 805 | Upholstered Furniture and Mattresses in New and Existing Buildings | 103 |

| 806 | Decorative Vegetation in New and Existing Buildings | 105 |

| 807 | Decorative Materials Other than Decorative Vegetation in New and Existing Buildings | 106 |

| 808 | Furnishings Other than Upholstered Furniture and Mattresses or Decorative Materials in New and Existing Buildings | 109 |

| CHAPTER 9 FIRE PROTECTION SYSTEMS | 117 | |

| Section | ||

| 901 | General | 117 |

| 902 | Definitions | 120 |

| 903 | Automatic Sprinkler Systems | 123 |

| 904 | Alternative Automatic Fire-Extinguishing Systems | 131 |

| 905 | Standpipe Systems | 134 |

| 906 | Portable Fire Extinguishers | 136 |

| 907 | Fire Alarm and Detection Systems | 144 |

| 908 | Emergency Alarm Systems | 158 |

| 909 | Smoke Control Systems | 158 |

| 910 | Smoke and Heat Vents | 164 |

| 911 | Explosion Control | 166 |

| 912 | Fire Department Connections | 168 |

| 913 | Fire Pumps | 168 |

| 914 | Fire Protection Based on Special Detailed Requirements of Use and Occupancy | 169 |

| CHAPTER 10 MEANS OF EGRESS | 177 | |

| Section | ||

| 1001 | Administration | 177 |

| 1002 | Definitions | 177 |

| 1003 | General Means of Egress | 178 |

| 1004 | Occupant Load | 180 |

| 1005 | Egress Width | 181 |

| 1006 | Means of Egress Illumination | 182 |

| 1007 | Accessible Means of Egress | 182 |

| 1008 | Doors, Gates and Turnstiles | 185 |

| 1009 | Stairways | 191 |

| 1010 | Ramps | 194 |

| 1011 | Exit Signs | 195 |

| 1012 | Handrails | 197 |

| 1013 | Guards | 198 |

| 1014 | Exit Access | 199 |

| 1015 | Exit and Exit Access Doorways | 201 |

| 1016 | Exit Access Travel Distance | 203 |

| 1017 | Aisles | 204 |

| 1018 | Corridors | 204 |

| 1019 | Egress Balconies | 206 |

| 1020 | Exits | 206 |

| 1021 | Number of Exits and Continuity | 206 |

| 1022 | Exit Enclosures | 207 |

| 1023 | Exit Passageways | 209 |

| 1024 | Luminous Egress Path Markings | 210 |

| 1025 | Horizontal Exits | 211 |

| 1026 | Exterior Exit Ramps and Stairways | 212 |

| 1027 | Exit Discharge | 212 |

| 1028 | Assembly | 214 |

| 1029 | Emergency Escape and Rescue | 218 |

| 1030 | Maintenance of the Means of Egress | 220 |

| CHAPTER 11 AVIATION FACILITIES | 225 | |

| Section | ||

| 1101 | General | 225 |

| 1102 | Definitions | 225 |

| 1103 | General Precautions | 225 |

| 1104 | Aircraft Maintenance | 225 |

| 1105 | Portable Fire Extinguishers | 226 |

| 1106 | Aircraft Fueling | 226 |

| 1107 | Helistops and Heliports | 231 |

| CHAPTER 12 DRY CLEANING | 235 | |

| Section | ||

| 1201 | General | 235 |

| 1202 | Definitions | 235 |

| 1203 | Classifications | 235 |

| 1204 | General Requirements | 235 |

| 1205 | Operating Requirements | 236 |

| 1206 | Spotting and Pretreating | 236 |

| 1207 | Dry Cleaning Systems | 237 |

| 1208 | Fire Protection | 237 |

| CHAPTER 13 COMBUSTIBLE DUST-PRODUCING OPERATIONS | 241 | |

| Section | ||

| 1301 | General | 241 |

| 1302 | Definitions | 241 |

| 1303 | Precautions | 241 |

| 1304 | Explosion Protection | 241 |

| CHAPTER 14 FIRE SAFETY DURING CONSTRUCTION AND DEMOLITION | 245 | |

| Section | ||

| 1401 | General | 245 |

| 1402 | Definitions | 245 |

| 1403 | Temporary Heating Equipment | 245 |

| 1404 | Precautions Against Fire | 245 |

| 1405 | Flammable and Combustible Liquids | 245 |

| 1406 | Flammable Gases | 246 |

| 1407 | Explosive Materials | 246 |

| 1408 | Owner’s Responsibility for Fire Protection | 246 |

| 1409 | Fire Reporting | 246 |

| 1410 | Access for Fire Fighting | 246 |

| 1411 | Means of Egress | 246 |

| 1412 | Water Supply for Fire Protection | 247 |

| 1413 | Standpipes | 247 |

| 1414 | Automatic Sprinkler System | 247 |

| 1415 | Portable Fire Extinguishers | 247 |

| 1416 | Motorized Equipment | 247 |

| 1417 | Safeguarding Roofing Operations | 247 |

| CHAPTER 15 FLAMMABLE FINISHES | 251 | |

| Section | ||

| 1501 | General | 251 |

| 1502 | Definitions | 251 |

| 1503 | Protection of Operations | 252 |

| 1504 | Spray Finishing | 253 |

| 1505 | Dipping Operations | 257 |

| 1506 | Powder Coating | 258 |

| 1507 | Electrostatic Apparatus | 259 |

| 1508 | Organic Peroxides and Dual-Component Coatings | 260 |

| 1509 | Indoor Manufacturing of Reinforced Plastics | 260 |

| 1510 | Floor Surfacing and Finishing Operations | 261 |

| CHAPTER 16 FRUIT AND CROP RIPENING | 265 | |

| Section | ||

| 1601 | General | 265 |

| 1602 | Definitions | 265 |

| 1603 | Ethylene Gas | 265 |

| 1604 | Sources of Ignition | 265 |

| 1605 | Combustible Waste | 265 |

| 1606 | Ethylene Generators | 265 |

| 1607 | Warning Signs | 265 |

| CHAPTER 17 FUMIGATION AND THERMAL INSECTICIDAL FOGGING | 269 | |

| Section | ||

| 1701 | General | 269 |

| 1702 | Definitions | 269 |

| 1703 | Fire Safety Requirements | 269 |

| CHAPTER 18 SEMICONDUCTOR FABRICATION FACILITIES | 273 | |

| Section | ||

| 1801 | General | 273 |

| 1802 | Definitions | 273 |

| 1803 | General Safety Provisions | 273 |

| 1804 | Storage | 277 |

| 1805 | Use and Handling | 278 |

| CHAPTER 19 LUMBER YARDS AND WOODWORKING FACILITIES | 285 | |

| Section | ||

| 1901 | General | 285 |

| 1902 | Definitions | 285 |

| 1903 | General Requirements | 285 |

| 1904 | Fire Protection | 285 |

| 1905 | Plywood, Veneer and Composite Board Mills | 286 |

| 1906 | Log Storage Areas | 286 |

| 1907 | Storage of Wood Chips and Hogged Material Associated with Timber and Lumber Production Facilities | 286 |

| 1908 | Storage and Processing of Wood Chips, Hogged Material, Fines, Compost and Raw Product Associated with Yard Waste and Recycling Facilities | 286 |

| 1909 | Exterior Storage of Finished Lumber Products | 287 |

| CHAPTER 20 MANUFACTURE OF ORGANIC COATINGS | 291 | |

| Section | ||

| 2001 | General | 291 |

| 2002 | Definitions | 291 |

| 2003 | General Precautions | 291 |

| 2004 | Electrical Equipment and Protection | 291 |

| 2005 | Process Structures | 292 |

| 2006 | Process Mills and Kettles | 292 |

| 2007 | Process Piping | 292 |

| 2008 | Raw Materials in Process Areas | 293 |

| 2009 | Raw Materials and Finished Products | 293 |

| CHAPTER 21 INDUSTRIAL OVENS | 297 | |

| Section | ||

| 2101 | General | 297 |

| 2102 | Definitions | 297 |

| 2103 | Location | 297 |

| 2104 | Fuel Piping | 297 |

| 2105 | Interlocks | 297 |

| 2106 | Fire Protection | 298 |

| 2107 | Operation and Maintenance | 298 |

| CHAPTER 22 MOTOR FUEL-DISPENSING FACILITIES AND REPAIR GARAGES | 301 | |

| Section | ||

| 2201 | General | 301 |

| 2202 | Definitions | 301 |

| 2203 | Location of Dispensing Devices | 301 |

| 2204 | Dispensing Operations | 302 |

| 2205 | Operational Requirements | 303 |

| 2206 | Flammable and Combustible Liquid Motor Fuel-Dispensing Facilities | 304 |

| 2207 | Liquefied Petroleum Gas Motor Fuel-Dispensing Facilities | 308 |

| 2208 | Compressed Natural Gas Motor Fuel-Dispensing Facilities | 309 |

| 2209 | Hydrogen Motor Fuel-Dispensing and Generation Facilities | 310 |

| 2210 | Marine Motor Fuel-Dispensing Facilities | 313 |

| 2211 | Repair Garages | 316 |

| CHAPTER 23 HIGH-PILED COMBUSTIBLE STORAGE | 321 | |

| Section | ||

| 2301 | General | 321 |

| 2302 | Definitions | 321 |

| 2303 | Commodity Classification | 322 |

| 2304 | Designation of High-Piled Storage Areas | 324 |

| 2305 | Housekeeping and Maintenance | 324 |

| 2306 | General Fire Protection and Life Safety Features | 327 |

| 2307 | Solid-Piled and Shelf Storage | 328 |

| 2308 | Rack Storage | 328 |

| 2309 | Automated Storage | 329 |

| 2310 | Specialty Storage | 329 |

| CHAPTER 24 TENTS AND OTHER MEMBRANE STRUCTURES | 333 | |

| Section | ||

| 2401 | General | 333 |

| 2402 | Definitions | 333 |

| 2403 | Temporary Tents and Membrane Structures | 334 |

| 2404 | Temporary and Permanent Tents and Membrane Structures | 336 |

| CHAPTER 25 TIRE REBUILDING AND TIRE STORAGE | 343 | |

| Section | ||

| 2501 | General | 343 |

| 2502 | Definitions | 343 |

| 2503 | Tire Rebuilding | 343 |

| 2504 | Precautions Against Fire | 343 |

| 2505 | Outdoor Storage | 343 |

| 2506 | Fire Department Access | 344 |

| 2507 | Fencing | 344 |

| 2508 | Fire Protection | 344 |

| 2509 | Indoor Storage Arrangement | 345 |

| CHAPTER 26 WELDING AND OTHER HOT WORK | 349 | |

| Section | ||

| 2601 | General | 349 |

| 2602 | Definitions | 349 |

| 2603 | General Requirements | 349 |

| 2604 | Fire Safety Requirements | 350 |

| 2605 | Gas Welding and Cutting | 351 |

| 2606 | Electric Arc Hot Work | 351 |

| 2607 | Calcium Carbide Systems | 351 |

| 2608 | Acetylene Generators | 351 |

| 2609 | Piping Manifolds and Hose Systems for Fuel Gases and Oxygen | 352 |

| CHAPTER 27 HAZARDOUS MATERIALS—GENERAL PROVISIONS | 355 | |

| Section | ||

| 2701 | General | 355 |

| 2702 | Definitions | 357 |

| 2703 | General Requirements | 365 |

| 2704 | Storage | 375 |

| 2705 | Use, Dispensing and Handling | 378 |

| CHAPTER 28 AEROSOLS | 385 | |

| Section | ||

| 2801 | General | 385 |

| 2802 | Definitions | 385 |

| 2803 | Classification of Aerosol Products | 385 |

| 2804 | Inside Storage of Aerosol Products | 385 |

| 2805 | Outside Storage | 387 |

| 2806 | Retail Display | 388 |